Our Products

Century Series Units – Xylem, Standard Xchange (ITT Standard)

The picture above may not represent the exact item you require.

Please contact us for more information on your item.

Description

The Century Series can meet TEMA “B”, “C”, and “R” specifications. Along with ASME Section VIII Div. 1 “U” stamp and ASME Section III “N” stamp.

Single or multi-pass tube arrangements are available for maximum efficiency over a wide variety of tube flow volumes. An expansion joint can be added to some of these models to compensate for severe temperature differentials. Standard shell sizes from 3 inches through 31 inches in diameter; with custom designs up to 60 inches in diameter. These units can be constructed from many different materials.

The Century Series is made up by the following models:

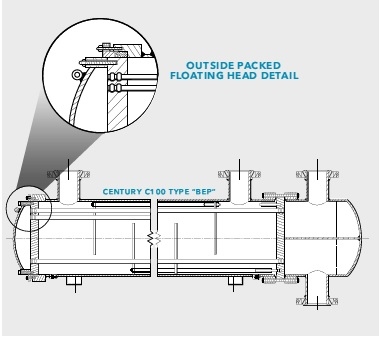

Model C100 - TEMA type AEP or BEP

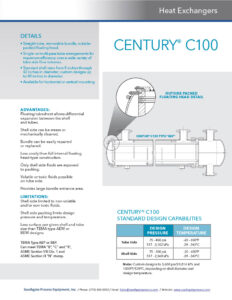

Model C100 Details:

- Straight Tube, removeable bundle, outside-packed floating head.

- Single or multi-pass tube arrangements for maximum efficiency over a wide variety of tube side flow volumes.

- Standard shell sizes from 8 inches through 42 inches in diameter; custom designs up to 60 inches in diameter.

- Available for horizontal or vertical mounting.

Advantages:

Floating tubesheet allows differential expansion between the shell and the tubes.Shell side can be steam or mechanically cleaned.

Bundle can be easily repaired or replaced.

Less costly than full internal floating head-type construction. Only shell side fluids are exposed to packing.

Volatile or toxic fluids possible on tube side.

Provides large bundle entrance area.

Century C100 Standard Design Capabilities

Xylem, Standard Xchange – ITT Standard

Design Pressure | Design Temperature | |

|---|---|---|

Tube Side | 75 – 450 psi / 517 – 3,102 kPa | -20 – 650°F

/ -29 – 343°C

|

Shell Side | 75 – 300 psi / 517 – 2,068 kPa | -20 – 650°F / -29 – 343 °C |

Note: Custom designs to 3,600 psi/24,816 kPa and 1000ºF/538ºC, depending on shell diameter and design temperature.

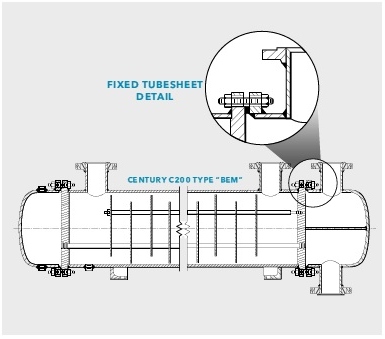

Model C200 / C210 - TEMA type AEM, BEM or NEN

Model C200 / C210 Details:

- Straight tube, fixed tubesheet, removeable channel or bonnet (C200), or integral channel (C210).

- Single or multi-pass arrangements for maximum efficiency over a wide variety of tube side flow volumes.

- An expansion joint can be added to compensate for severe temperature differentials.

- Standard shell sizes from 5 inches through 42 inches diameter; custom designs up to 60 inches in diameter.

- Available for horizontal or vertical mounting.

ADVANTAGES:

Less costly than removable bundle exchangers.Provides maximum heat transfer surface area per given shell and tube size.

Easily interchangeable with designs of various other manufacturers.

Tube side can be steam or mechanically cleaned.

Only tube side fluids are exposed to gaskets.

Volatile or toxic fluids possible on shell side.

Easy accessibility for tube side cleaning and inspection.

No packed joints.

CENTURY® C200 and C210 STANDARD DESIGN CAPABILITIES

Xylem, Standard Xchange – ITT Standard

Design Pressure | Design Temperature | |

|---|---|---|

Tube Side | 75 – 450 psi / 517 – 3,102 kPa | -20 – 650°F

/ -29 – 343°C

|

Shell Side | 75 – 300 psi / 517 – 2,068 kPa | -20 – 650°F / -29 – 343 °C |

Note: Custom designs to 3,600 psi/24,816 kPa and 1000ºF/538ºC, depending on shell diameter and design temperature.

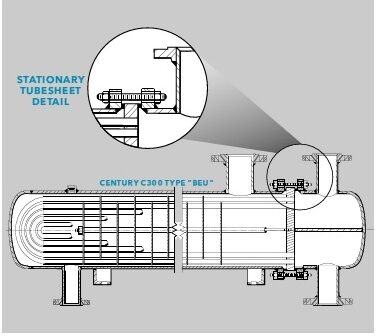

Model C300 / C320 - TEMA type AEU or BEU

Model C300 / C320 Details:

- U-tube, removable bundle (C300) or suctionheater (open-end shell) construction (C320).

- Multi-pass tube arrangements for maximum efficiency over a variety of tube side flow volumes.

- The C320 is much like the C300, but has an open-end shell and special tube layout for tank suction heating applications.

- Standard shell sizes from 5 inches through 42 inches in diameter; custom designs up to 60 inches in diameter.

- Available for horizontal or vertical mounting.

ADVANTAGES:

Allows for differential thermal expansion between shell and tubes as well as between individual tubes.High heat transfer surface area for given shell and tube size.

Capable of withstanding thermal shock.

The most economical of all shell- and-tube exchangers, and the least expensive of all basic designs.

Shell side can be steam or mechanically cleaned.

Bundle can be removed for shell side cleaning and maintenance.

CENTURY® C300 and C320 STANDARD DESIGN CAPABILITIES

Xylem, Standard Xchange – ITT Standard

Design Pressure | Design Temperature | |

|---|---|---|

Tube Side | 75 – 450 psi / 517 – 3,102 kPa | -20 – 650°F

/ -29 – 343°C

|

Shell Side | 75 – 300 psi / 517 – 2,068 kPa | -20 – 650°F / -29 – 343 °C |

Note: Custom designs to 3,600 psi/24,816 kPa and 1000ºF/538ºC, depending on shell diameter and design temperature.

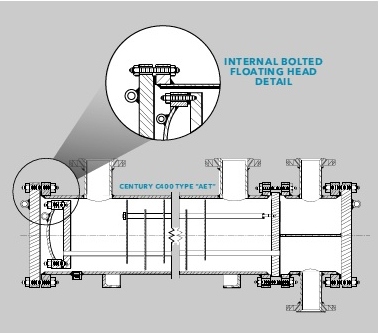

Model C400 - TEMA type AET or BET

Model C400 Details:

- Straight tube, internally bolted floating head, pull-through construction with removable bundle.

- Multi-pass tube arrangements for maximum efficiency over a wide variety of tube side flow volumes.

- Standard shell sizes from 8 inches through 42 inches in diameter; custom designs up to 60 inches in diameter.

ADVANTAGES:

Bundle can be removed from shell for cleaning or maintenance.Lack of packed joints allows for handling volatile or toxic fluids.

Large bundle entrance area.

Allows for differential thermal expansion between shell and tubes.

Bundle can be pulled without removing floating head cover.

CENTURY® C400 STANDARD DESIGN CAPABILITIES

Xylem, Standard Xchange – ITT Standard

Design Pressure | Design Temperature | |

|---|---|---|

Tube Side | 75 – 450 psi / 517 – 3,102 kPa | -20 – 650°F

/ -29 – 343°C

|

Shell Side | 75 – 300 psi / 517 – 2,068 kPa | -20 – 650°F / -29 – 343 °C |

Note: Custom designs to 3,600 psi/24,816 kPa and 1000ºF/538ºC, depending on shell diameter and design temperature.

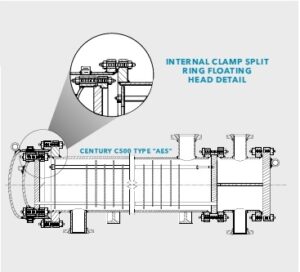

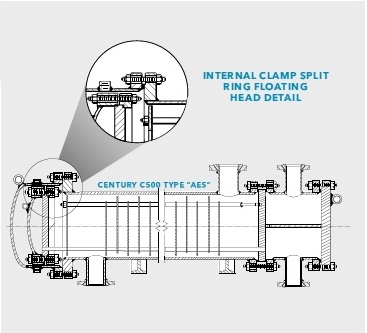

Model C500 - TEMA type AES or BES

Model C500 Details:

• Straight tube, internal clamp split ring, floating head, removable bundle.

• Multi-pass tube arrangements for maximum efficiency over a wide variety of tube flow volumes.

• Standard shell sizes from 6 inches through 42 inches in diameter; custom designs

up to 60 inches in diameter.

• Available for horizontal or vertical mounting.

ADVANTAGES:

Higher heat transfer surface area per given shell and tube size than pull-through designs (AET or BET Types).Allows for differential thermal expansion between the shell and tubes.

Lack of packed joints allows for handling volatile and/or toxic fluids.

Provides multi-pass tube arrangements.

Bundle can be removed for shell side cleaning and maintenance.

CENTURY® C500 STANDARD DESIGN CAPABILITIES

Xylem, Standard Xchange – ITT Standard

Design Pressure | Design Temperature | |

|---|---|---|

Tube Side | 75 – 450 psi / 517 – 3,102 kPa | -20 – 650°F

/ -29 – 343°C

|

Shell Side | 75 – 300 psi / 517 – 2,068 kPa | -20 – 650°F / -29 – 343 °C |

Note: Custom designs to 3,600 psi/24,816 kPa and 1000ºF/538ºC, depending on shell diameter and design temperature.

Contact us for more information on the above products:

Email: sales@southgatepe.com

Phone: (770) 345-0010

You May Also Like...

Request A Quote

"*" indicates required fields