XYLEM HEAT TRANSFER EQUIPMENT

Southgate Process Equipment has been a top authorized distributor for Standard Xchange, a Xylem brand, for over 25 years.

Southgate maintains a large inventory of complete units and spare parts in stock for fast deliveries. If you need a particular part or item please click here to request a quote or call us @ (770) 345-0010.

Xylem specializes in bringing together advanced technologies, application expertise, and smart sustainable solutions for water across a wide range of industries and applications. Xylem is the parent company of Standard Xchange heat exchangers, formerly ITT Standard and American Standard.

Xylem specializes in bringing together advanced technologies, application expertise, and smart sustainable solutions for water across a wide range of industries and applications. Xylem is the parent company of Standard Xchange heat exchangers, formerly ITT Standard and American Standard.

Xylem is the leader in industrial heat transfer, with a complete line of plate and frame, shell and tube, brazed plate, and air-cooled heat exchangers for the chemical, pulp and paper, biofuel, sugar processing, petroleum, power generation, mining, and general industrial markets. We can provide models for high temperature, high pressure, and corrosive environments, as well as sanitary configurations for pharmaceutical and food and beverage processing.

Whether you are looking for air coolers, heat transfer coils, compact brazed, shell and tube, gasketed plate units, or packaged steam condensers, Southgate Process Equipment and Xylem can connect you with the units and parts you require.

Removable U-Tube Heat Exchangers (ASME Section VIII Div. 1 Code Stamp):

Standard Units have a (1-2) week delivery after purchase order is received.

Expediting options are available please contact us for more information (770) 345-0010.

U-tube, removable floating bundle heat exchangers with copper tubes, available in 2, 4 and 6 pass arrangements covering areas up to 1,900 square feet for optimal performance in a variety of applications. ASME Section VIII Div. 1 U Stamp as standard.

SX2000U uses compact 3/8 inch OD tubes, with pre-engineered units offering shell diameters from 4-12 inches. B300 models use larger 3/4 inch OD tubes and shell diameters from 4-30 inches to handle a wide range of fluids.

The removable floating bundle design allows for differential thermal expansion between the shell and tubes as well as between the individual tubes, making the system capable of withstanding thermal shock. The all welded rugged carbon steel shell side construction provides maximum durability. The design provides maximum heat transfer surface area per given shell and tube size, and is interchangeable with designs from other manufacturers.

The shell comes standard in fabricated Carbon Steel, with Stainless options available. Tube sheets are Fabricated Carbon Steel with Stainless, 90/10 CuNi, and Brass options. Tubes come standard in Copper, with options for Stainless Steel, or 90/10 or 70/30 CuNi. Cast Iron Bonnets are also available in Cast 316 Stainless Steel or Cast Bronze options. Feet and bolting are Carbon Steel.

APPLICATIONS

For heating water or other fluids, using steam or water as the heating/cooling medium.

Pre-Engineered Shell and Tube Heat Exchangers:

Standard Units have a (1-2) week delivery after purchase order is received.

Expediting options are available please contact us for more information (770) 345-0010.

Straight tube, fixed tubesheet heat exchanger available in 1, 2 and 4 tube side pass configurations. Shell diameters range from 2 inches through 8 inches. Tubes are copper, with an option for 90/10 or 70/30 CuNi, and are available in 1/4 inch, 3/8 inch, and 5/8 inch OD. Standard tube lengths range from 8 inches to 72 inches, with custom tube lengths to 144 inches. Brass hubs with optional SAE four bolts connections. Carbon steel feet and bolting. Custom design options include special tube lengths, baffle spacing, nozzle orientations, and location of feet.

Less costly than removable bundle heat exchangers, while still providing maximum heat transfer surface area. Interchangeable with designs from different manufacturers. Flanged lip baffles ensure close tolerance, high efficiency, and additional tube support. Enlarged bundle entrance area of the hub/tubesheet design lowers entrance velocity and pressure loss. Tube side can be steam or mechanically cleaned. Only tube side fluids are exposed to gaskets. No packed joints.

APPLICATIONS

To heat or cool water or lube oil, or condense steam. Use for auxiliary machinery, turbines, engines, and compressors. An excellent choice for pilot plants.

Straight tube, fixed tubesheet heat exchanger with all fluid contact parts made from 316 stainless steel. Compact design with shell diameters 2 to 8 inches. Standard tube lengths range from 8 inches to 72 inches, with custom tube lengths available to 144 inches. Heat transfer surfaces range from 1.2 square feet to 576 square feet with 1, 2 or 4 tube side pass options. ASME Code options and flanged connections are available.

Shell is 316 Stainless Steel with 316 Stainless Steel tubes, hubs, and bonnets. Tubes can also be configured in Copper, 90/10, or 70/30 CuNi with 1/4 inch, 3/8 inch, or 5/8 inch tube diameter options. Bonnets are also available in Cast Iron and Cast Bronze. Standard feet and bolting are Carbon Steel, with a Stainless option. Tube side can withstand pressures up to 150 psi (10.5 kg/cm²) and temperatures to 450°F (232°C). Shell side pressures to 225 psi (15.8 kg/cm²) and temperatures to 450°F (232°C).

Costs less than removable bundle exchangers, while providing maximum heat transfer surface area per given shell and tube size. Interchangeable with other manufacturers’ designs. Flanged lip baffles ensure close tolerance with high efficiency and additional tube support. The enlarged bundle entrance area of the hub/tubesheet design lowers entrance velocity and reduces pressure loss. Tube side can be steam or mechanically cleaned. Only tube side fluids are exposed to gaskets. No packed joints.

APPLICATIONS

For heating or cooling corrosive fluids in chemical, pharmaceutical or refining processes.

Straight tube, fixed tubesheet heat exchanger available in 1, 2 and 4 tube side pass configurations, covering areas up to 136.7 square feet. Shell diameters range from 2 to 8 inches, with standard tube lengths from 8 inches to 72 inches, and custom tube lengths up to 144 inches. ASME Code options and flanged connection options are also available.

Maximum durability is provided by the all welded rugged carbon steel shell side construction. Tube sheets are fabricated carbon steel with an option for Stainless Steel 316 or 90/10 CuNi. Tubes come standard in copper, with the option for 316 Stainless Steel, 90/10 or 70/30 CuNi. Tube diameters are available from 1/4 inch to 3/8 inch. Cast Iron bonnets with cast 316 Stainless Steel and Cast Bronze options. Feet and bolting are Carbon Steel.

Costs less than removable bundle exchangers, while providing maximum heat transfer. Interchangeable with designs of various manufacturers. Tube side can be steam or mechanically cleaned. Only tube side fluids are exposed to gaskets. No packed joints.

APPLICATIONS

To cool lube oil, fluids or jacket water, and for use where brass is not practical.

Custom Engineered Shell and Tube Units:

Standard Units have a (1-2) week delivery after purchase order is received.

Expediting options are available please contact us for more information (770) 345-0010.

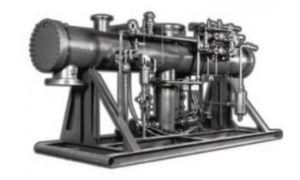

Xylem’s Century Series heat exchangers are available in a variety of models and configurations to suit your requirements. The Century Series can meet TEMA “B”, “C”, and “R” specifications, along with ASME Section VIII Div. 1 “U” stamp and ASME Section III “N” stamp.

Single or multi-pass tube arrangements are available for maximum efficiency over a wide variety of tube flow volumes, and these units can be constructed from many different materials.

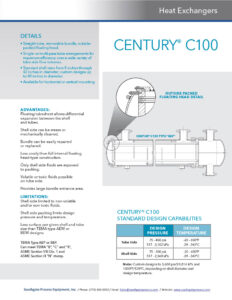

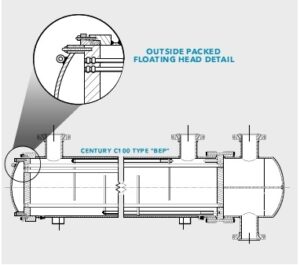

Straight tube, removable bundle, outside-packed floating head. TEMA type AEP or BEP. Single or Multi-pass tube arrangements for maximum efficiency over a wide variety of tube side flow volumes. Standard shell sizes from 8" through 42" in diameter, with custom designs up to 60" in diameter. Available for horizontal or vertical mounting. (Brochure)

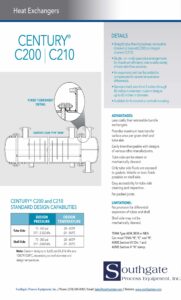

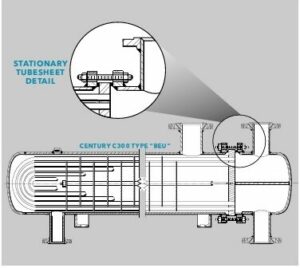

Straight tube, fixed tubesheet, with removable channel or bonnet. TEMA type AEM, BEM, or NEN. Can meet TEMA B, C, and R, ASME Section VIII Div. 1, and ASME Section III N stamp. Single- or multi-pass tube arrangements for maximum efficiency over a range of tube side flow volumes. An expansion joint can be added to compensate for severe temperature differentials. Standard shell diameters from 5" through 42" and custom designs up to 60" in diameter. Available for horizontal or vertical mounting. (Brochure)

Straight tube, fixed tubesheet, with integral channel. TEMA type AEM, BEM, or NEN. Can meet TEMA B, C, and R, ASME Section VIII Div. 1, and ASME Section III N stamp. Single- or multi-pass tube arrangements for maximum efficiency over a range of tube side flow volumes. An expansion joint can be added to compensate for severe temperature differentials. Standard shell diameters from 5" through 42" and custom designs up to 60" in diameter. Available for horizontal or vertical mounting. (Brochure)

U-tube, removable bundle heat exchanger. TEMA Type AEU or BEU. Can meet TEMA B, C, and R, ASME Section VIII Div. 1, and ASME Section III N stamp. Multi-pass tube arrangements for maximum efficiency, allowing for differential thermal expansion between shell and tubes as well as between individual tubes. Capable of withstanding thermal shock. The most economical of all shell-and-tube heat exchangers, and the least expensive of all basic designs. Bundle can be removed for shell side cleaning and maintenance. (Brochure)

Much like the C300, but has an open-end shell and special tube layout for tank suction heating applications. TEMA Type AEU or BEU. Can meet TEMA B, C, and R, ASME Section VIII Div. 1, and ASME Section III N stamp. Multi-pass tube arrangements for maximum efficiency, allowing for differential thermal expansion between shell and tubes as well as between individual tubes. Capable of withstanding thermal shock. (Brochure)

Straight tube, internally bolted floating head, pull-through construction with removable bundle. TEMA type AET or BET. Can meet TEMA B, C, and R, ASME Section VIII Div. 1, and ASME Section III N stamp. Bundle can be removed from shell for cleaning or maintenance. Lack of packed joints allows for handling volatile or toxic fluids. Large bundle entrance area. Bundle can be pulled without removing floating head cover. (Brochure)

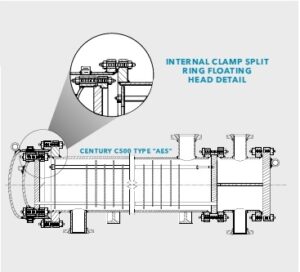

Straight tube heat exchanger with internal clamp split ring, floating head, and removable bundle. TEMA type AES or BES. Higher heat transfer surface area per given shell and tube size than pull-through designs (AET or BET types). Allows for differential thermal expansion between the shell and tubes. Lack of packed joints allows for handling of volatile and/or toxic fluids. Bundle can be removed for shell side cleaning and maintenance. (Brochure)

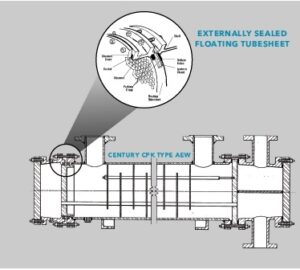

Xylem’s Model CPK is a straight tube, removable bundle, packed floating tubesheet heat exchanger. The CPK can meet TEMA “B”, “C”, and “R” specifications, as well as ASME Section VIII Div. 1 “U” stamp and ASME Section III “N” stamp.

The CPK has single or two pass tube arrangements for maximum efficiency over a wide variety of tubeside flow rates. It is available in horizontal as well as vertical installations, as well as stacked assemblies.

Straight tube heat exchanger with removable bundle and packed, floating tubesheet. TEMA Type AEW or BEW. Can meet TEMA B, C, and R, ASME Section VIII Div. 1 U stamp, and ASME Section III N stamp. Standard shell sizes from 3" through 31" in diameter, with custom designs up to 60" in diameter. Available in horizontal and vertical installations as well as stacked assemblies. Less costly than full internal floating head type construction. (Brochure)

Brazed Plate Heat Exchangers:

Delivery for Standard Units is 1-2 weeks after purchase order is received.

Options are available for expedited deliver. Please contact us for more information at (770) 345-0010.

Xylem’s unique heat transfer plate designs provide high rates of heat transfer, requiring less surface area than conventional shell and tube heat exchangers. BrazePak Brazed Plate Heat Exchangers are one-sixth the size and one-fifth the weight of conventional shell and tube units, using only one-eighth the liquid and requiring one-third to one-fifth the surface area. They offer the highest level of thermal efficiency and durability in a compact, low-cost unit.

The corrugated plate design provides very high heat transfer coefficients in a smaller surface area, making the BrazePak an excellent choice, especially where space is a consideration. Thin corrugated stainless steel plates are vacuum brazed together to form a very durable, integral piece that can withstand both high pressure and high temperature in a solid, self-contained unit.

BrazePak Brazed Plate Heat Exchangers are ideal as refrigerant condensers and evaporators, subcoolers, and desuperheaters, and for oil, water, and gas cooling in many other industrial, residential, commercial, and HVAC applications, ranging from compressors, hydraulic packages, lasers, diesel engines, and machinery.

BP models available with copper or nickel brazing and 316 S/S plates. Vacuum-brazed, stacked plate construction, Copper Braze as standard with optional Nickel braze material available. Max Flow – 800 GPM with areas up to 365 Sq. Ft. Connections are 316L stainless steel and range from 1/2″ OD to 4″ OD connections in MNPT, FNPT, Sweat, SAE threaded, Flanged, Victaulic grooved, Hose barb, etc. with custom connections available. Mounting options also available such as: threaded studs or integral mounting bracket. Available codes include UL, CRN, ASME Code and CE/PED.

Gasketed Plate and Frame Heat Exchangers:

Delivery for Standard Units is 1-2 weeks after purchase order is received.

Options are available for expedited deliver. Please contact us for more information at (770) 345-0010.

Xylem’s Plateflow gasketed plate and frame heat exchanger offers a compact, efficient, and flexible design that is easy to install and move, readily expandable, and easy to inspect or clean.

Plateflow gasketed plate and frame heat exchangers are available in a variety of plate construction materials, including 304 or 316 Stainless Steel, Titanium, Hastelloy® , Incolloy® , and other metals. Various connection types are available to match the application requirements. Gasketed, semi-welded, double wall, and free flow plates are designed to meet a wide variety of applications.

Air Cooled Heat Exchangers:

Delivery for Standard Units is 1-2 weeks after purchase order is received.

Options are available for expedited deliver. Please contact us for more information at (770) 345-0010.

Compact, dependable bar and plate design, air-cooled unit. Thermally efficient. Up to 65% smaller than Fin Tube designs. Non-louvered fin design provides high heat transfer rates, prevents clogging, and is easy to clean. Low noise options offer slower fan speeds for reduced noise level and lower fan hp requirements.

SPECIFICATIONS

Max. Working Pressure (ARX5 through ARX130) … 377 psi

Max. Working Pressure (ARX160 through ARX275) … 250 psi

Max. Working Temperature … 250°F

MATERIALS

Cooler … Aluminum

Shroud … Powder, Painted Steel

Fan Guard … Zinc, Plated Steel

Fan Blade … Polypropylene Blades / Aluminum Hub

Mounting Brackets … Powder, Painted Steel

FanEx Heat Exchangers are available in Air-to-Oil (F700) and Air-to-Water/Glycol (F740) models. Heavy-gauge galvanized steel housing and rigid frame provide sturdy, dependable support for long life and maximum safety in the most demanding day-to-day plant operating environments. Heavy duty direct-drive fan and airfoil housings are designed with close-fitting tolerances for maximum performance and minimum sound levels.

Heavy-walled copper headers with brazed tube joints provide resistance to corrosion and vibration. All Air/Oil models feature exclusive, patented amaspher turbulation to mix oil for better cooling in less space. Twelve standard sizes with oil flows from 2 to 180 gallons per minute.

FanEx units allow you to:

- Locate your cooler in a convenient location when cooling water piping is not located nearby.

- Control viscosity in hydraulic systems, thereby promoting longer life of component parts. In similar fashion, units can be used for controlling viscosity of oils in lubricating oil systems.

- Design a closed cooling system.

REQUEST A QUOTE

"*" indicates required fields