Temptek

Southgate Process Equipment is an authorized distributor for Temptek and all of their products, offering better pricing than the factory can direct.

Click here to request a quote or call us @ (770) 345-0010.

Temptek, Inc. has revolutionized today’s market of low cost auxiliary equipment for the industry. Our product philosophy is to provide you with economically affordable equipment, built for round the clock operations, providing years of trouble-free service, offering users maximum returns on their capital investments.

Temptek, Inc. has revolutionized today’s market of low cost auxiliary equipment for the industry. Our product philosophy is to provide you with economically affordable equipment, built for round the clock operations, providing years of trouble-free service, offering users maximum returns on their capital investments.

All Temptek products are backed by a 1 year parts and labor warranty. Some products carry special warranties beyond our standard 1 year warranty. For example, we offer 10 year shell warranties on our fiberglass tower cells and polyethylene pump tanks. See individual product brochures for more information.

Temptek offers many types of auxiliary equipment such as:

Portable Water Chillers:

DETAILS on the CF, CG, and CGD SERIES:

These units use a refrigerant zone with a compressor and evaporator, with reservoir and coolant pump. Water-cooled models use a plant water source for condensing, and air-cooled use fans or blowers to move ambient air across the condenser.

- Supply Temperature Range 20° – 70°F

- Available from 1/4 to 40 tons

- Microprocessor Control

- Galvanized Steel Frame

- Nonferrous Coolant Circuit

- Non Ozone Depleting Refrigerants

- Contact Us for Discounted Pricing! (770) 345-0010

- ¼ – 1½ Tons of Capacity

- Microprocessor Control

- Air-Cooled Condenser

- Galvanized Steel Frame

- Nonferrous Coolant Circuit

- Non Ozone Depleting Refrigerants

The CG-A Series portable chiller provides precision temperature control from an economically affordable and reliable unit. Perfect for applications such as plastic injection molding, blow molding, extrusion and other industrial applications.

- 4 – 40 Tons of Capacity

- 20°F – 80°F Fluid Temperatures

- Indoor Chiller Unit with Integral

- Air-Cooled Condenser

- R410A Non Ozone Depleting Refrigerant

- Steel Frame & Lift-Off Cabinetry

- Stainless Steel Brazed Plate Evaporator

CG-W Series Water-Cooled Portable Water Chillers (2 - 40 tons)

The CG-W Series portable chiller provides precision temperature control from an economically affordable and reliable unit. Perfect for applications such as plastic injection molding, blow molding, extrusion and other industrial applications.

- 2 – 40 Tons of Capacity

- 20°F – 80°F Fluid Temperatures

- Water-Cooled Condenser

- R410A Non Ozone Depleting Refrigerant

- Steel Frame & Lift-Off Cabinetry

- Stainless Steel Brazed Plate Evaporator

- 5 – 15 Ton Models

- 20°F – 80°F Fluid Temperatures

- Digital Scroll Compressor Technology

- R410A Non Ozone Depleting Refrigerant

- Steel Frame & Lift-Off Cabinetry

- Stainless Steel Brazed Plate Evaporator

Central Water Chillers:

DETAILS on the TTI, TT-OACS, and MA-RC SERIES:

Central water chillers are designed to circulate a fluid medium (typically water, or a water-glycol solution) through a process application for Cooling.

- Supply Temperature Range 20° – 65°F

- Provide enough capacity to serve multiple process applications

- Capacities from 5 to 180 tons

- For best pricing, Contact Us at (770) 345-0010

The TTI Series offers a complete central chiller and pump tank package. Available in Air-Cooled (with remote condenser) and Water-Cooled models.

- 20 – 280 Tons of Capacity

- Customized smaller and larger systems available

- 20°F – 80°F Process Fluid Temperatures

- For Indoor Installation

- Multiple Refrigerant Zones

- Water Distribution System

The TT-OACS Series with Integral Air-Cooled Condenser is designed for outdoor installation in many climates. The fully charged air-cooled refrigerant chiller and pump tank station are packaged in a single frame which minimizes field installation.

- 20 – 2,100 Tons of Capacity

- 20°F – 65°F Process Fluid Temperatures

- For Outdoor Installation

The MA-RC Series central chiller provides precision temperature control from an economically affordable and reliable unit. Perfect for applications such as plastic injection molding, blow molding, extrusion and other industrial applications. A pump tank station is required to distribute the chilled water to the application use-points.

The MA-RC model allows for the primary chiller to stay indoors, while the remote condenser is installed outdoors. Chilling modules are offered in single, dual and triple zone configurations.

- 5 – 180 Tons of Capacity

- Uses Non-Ozone Depleting Refrigerants

- Microprocessor Control

- Remote Air-Cooled Condenser

- Galvanized Steel Frame

Temperature Control Units:

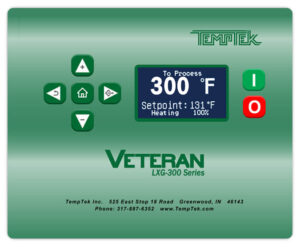

DETAILS on the VETERAN (VT) SERIES:

Temptek’s Veteran Series (VT) temperature control unit is the new Old Soldier for temperature control. Designed by skilled and experienced Veteran Engineers that know the industry. This temperature control unit is designed for your needs and built for long-term dependable full-time operations. For precise temperature control, no other controller beats the VT Series model.

- Water (VT) and Oil (VTO) Systems Available

- Stainless Steel Cabinetry

- Contact Us at (770) 345-0010 to discuss customization options at the best pricing to meet your needs

Water Temperature Control Units:

VT Series Water Temperature Control Units circulate water through the process application for temperature control.

- LXG Series Control Instrument

- Modulating Cooling Valve

- Operating Temperatures to 250°F

- Heaters to 34 kW

- Pumps to 7.5 HP

- LS Series Control Instrument

- Solenoid Cooling Valve

- Operating Temperatures to 250°F

- Heaters to 34 kW

- Pumps to 7.5 HP

- LXT Series Control Instrument

- Modulating Cooling Valve

- Operating Temperatures to 250°F

- Heaters to 34 kW

- Pumps to 7.5 HP

- LXG-300 Series Control Instrument

- Solenoid Cooling Valve

- Operating Temperatures to 300°F

- Heaters to 34 kW

- Pumps to 7.5 HP

Oil Temperature Control Units:

VTO Series Oil Temperature Control Units circulate hot oil through the process application for temperature control.

VTO Series (Hot Oil Unit)

• 100°F – 500°F Process Temperatures

• 1 – 7½ HP Centrifugal Pumps (20 – 100 GPM)

• 12 – 48 kW Heaters

• 3.4 sq. ft. Heat Exchanger

• Customize A Unit to Meet Your Specific Requirements

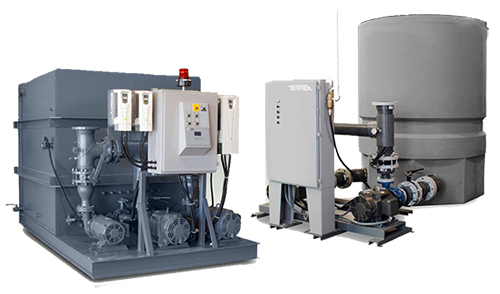

Pump Tank Stations:

DETAILS on the PPT and PT Series:

Temptek’s pump tank systems support cooling equipment including evaporative cooling towers, central chillers and fluid coolers. A vented reservoir with fluid pumps and controls specifically selected to meet the needs of your process and/or entire facility. The standard unit is designed to be installed indoors or protected from the elements.

Use of a pump tank assembly improves plant cooling effectiveness by providing a stable reserve of cooling fluid to moderate the effects of rapid load changes.

PACKAGE CHILLERS

- Capacities from 200 – 3,000 Gallons

- Tower or Chiller Water Systems

- Pumps from 2 – 60 HP

- Flows from 40 – 1,250 GPM

- For best pricing Contact Us at (770) 345-0010

Polyethylene PPT Series

- Cylindrical, seamless one piece tank

- Rotational molded from linear low density polyethylene

- A baffle provides hot and cold water service

- Pump assemblies are mounted on a structural steel deck and attached via flexible connectors

- Rectangular base offers greater stability and expansion capacity

- Tank lid is included

- 400, 800, 1,500 & 3,000 Gallon Capacities

- Engineered Pump Selections to Meet Your Flow & Pressure Requirements

- 10 Year Tank Failure Warranty

Mild & Stainless Steel PT Series

- 10 Gauge Stainless or 7 Gauge Mild Steel

- Welded into form with perimeter belting to increase strength

- Wetted surfaces on mild steel tanks receive a thick layer of 2 part epoxy coating

- A partition inside the tank serves as a hot and cold divider

- Set onto a structural steel base

- The base area not immediately underneath the tank is decked with sheet metal and becomes the pump platform

Cooling Towers:

DETAILS on the TP Series Cooling Tower:

The TP Series cooling tower is ready to meet the needs of todayʼs industry. This tower cell is made of all non-ferrous materials, including fiberglass shell, TEFC motor, ABS fan, PVC wet deck and distribution header. The fiberglass shell is 1/2” thick and even thicker in certain support areas. Other product features include:

- All Non-Ferrous Design

- 45 – 540 Tons Capacity

- UV Stabilized Fiberglass Shell

- TEFC Fan Motor with ABS Fan Blades

- Single or Multi Cell Designs

- Easily Removable Inspection Covers with Seamless Gasket Sealing

- 10 Year Shell Warranty

- 5 Year Mechanical Warranty

- For best pricing Contact Us at (770) 345-0010

Granulators:

DETAILS on the EM Series Granulator:

The EM Series is designed for maximum versatility. This press side granulator is operator friendly, easy to service and maintain. Precision scissor cut action provides maximum through-put efficiency. Product features include:

- 4 Models to Choose From

- Manual or Robotic Feed

- Interlock Time Delay Safety

- D2 High Carbon Steel Knives

- Tangential Feed Design

- Hinged Hopper and Screen Cradle for Easy Cleaning and Servicing

- Low Noise: Engineered to meet 90 DBA or less for most materials

- For best pricing Contact Us at (770) 345-0010

Vacuum Loaders:

DETAILS on the VL Series Vacuum Loader:

Temptek VL Series Vacuum Loaders provide self-contained, vacuum transfer of plastic pellets and regrinds over short distances using powerful single-phase vacuum motors. Standard models are made for flange mounting to existing bins or hoppers. Machine Mount packages provide a quick disconnect glass tube base with integrated vacuum flapper. A proportioning valve option may be easily added to any model.

- Reinforced filter disc has polyester layer to trap fines and rigid metal backing to extend filter life.

- Compressed-air blowback reduces filter clogging for

less maintenance. - Includes 15 ft. (4.6m) length of flex hose,

pickup wand and hose clamps. - All material contact points are non-ferrous.

- Dump Valve with integrated demand level switch on

standard models. - Micro PLC Based Control can be remotely located at operator level.

- Modular Design.

- 5, 12, or 19 lb Resin Capacity.

- Three Models to choose from: VL-5-T, VL-12-T, VL-19-T.

- One Year warranty (Excludes normal maintenance items.)

- MADE IN THE USA!

- Contact Us for best pricing at (770) 345-0010

Desiccant Dryers:

DETAILS on the NDB Series Desiccant Dryer:

Temptek NDB Series Desiccant Dryers use the industry standard dual-bed drying concept in a compact single blower configuration. One blower and multi-function valve control both the process and regeneration flow and the heaters are contained within the desiccant beds to minimize space.

- Self-Contained Dryer/ Hopper Design

- Throughput 15 – 50 lb/hr

- 3 Models to choose from: NDB-15-T, NDB-25-T, NDB-50-T

- Guaranteed -40ºF dewpoint process air

- Dual bed, stainless steel construction

- Integrated stainless steel insulated drying hoppers with large access door and sight glass (200 lb. hopper is carbon steel)

- Standard voltage 115/1/60 for NDB-15-T, 460/1/60 for NDB-25-T and 460/3/60 for NDB-50-T

- Cyclonic 2 stage process filter

- High heat up to 350° F (cooling coil required over 225° F)

- Tubular Incoloy® sheath heaters

- Nema 1 enclosure

- Main line contactor

- High efficiency 13X molecular sieve desiccant

- Slide gate shut off

- Analog thermometer at hopper inlet

- 1 Year warranty

- MADE IN THE USA!

- Contact Us for best pricing at (770) 345-0010

Please Contact us for more information about Temptek and their products.

Email: sales@southgatepe.com

Phone: (770) 345-0010

REQUEST A QUOTE

"*" indicates required fields