Munters Product Line

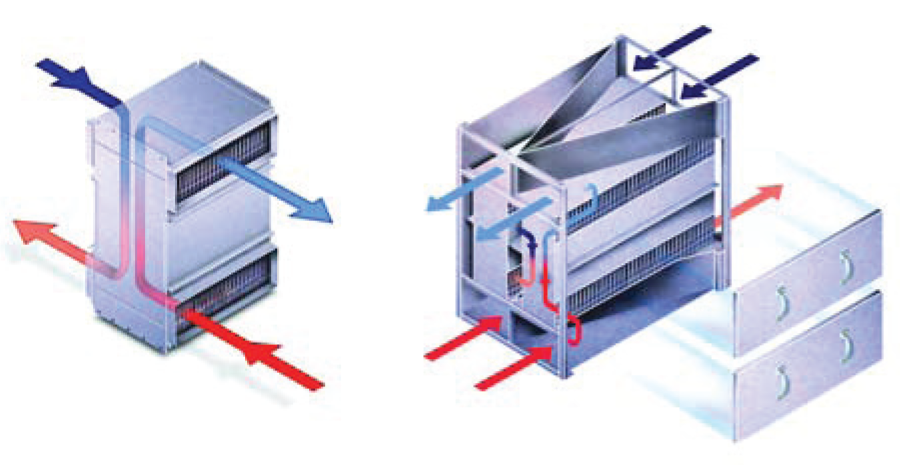

Z-DUCT® Series 74

This series features the basic building block found in all Z-DUCT heat recovery systems. These economical units include built-in drains and removable cleanout panels. All units, which can be field installed in multiples to meet specific CFM requirements, have a nominal flow rate of 1000 CFM and can be fabricated from various materials to enable operation to 400°F.

Z-DUCT® Series 75

This series features a modular designed counterflow air-to-air energy recovery unit with complete separation between air streams. Removable cleanout panels provide easy access to the heat transfer medium for inspection and cleaning. An optional automatic water-wash system results in years of maintenance-free operation. Available with nominal flow ratings from 4,000 to 10,000 CFM and can be fabricated from various materials to enable operation to 400°F.

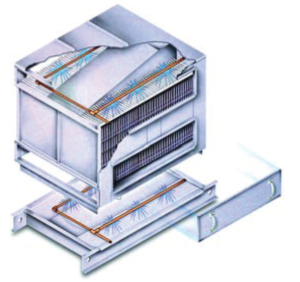

Z-DUCT® Series 85

This series features a modular designed counterflow air-to-air energy recovery unit which is designed to recover energy from a process with particulate laden exhaust. Standard features include removable cleanout panels for easy access to the heat transfer medium for inspection and cleaning and a fully welded sloped drain pan with a 3″ drain connection. The standard options for double wall insulated construction and industrial water-wash systems result in years of maintenance-free operation. Available with nominal flow ratings from 4,000 to 30,000 CFM and can be fabricated from various materials to enable operation to 400°F.

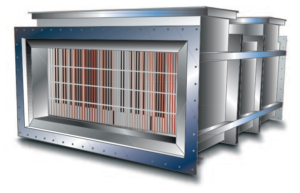

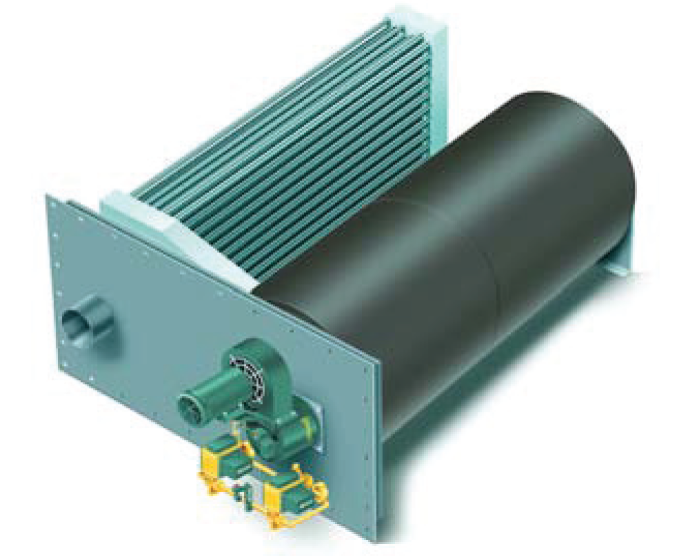

Thermo-Z is a welded plate heat exchanger, custom designed to recover energy from processes up to 1400°F. Recovered energy can be recovered and returned as process make-up air used to preheat combustion air or used for plant or office heating. Factory tested for .01% max leakage at standard 20″ W.C. differential pressure rating. Customized for each application with variable plate sizes and spacings, flexible materials of construction, and seven (7) flow patterns to simplify ducting. Standard options include 4″ thermal insulation and integral expansion compensation..

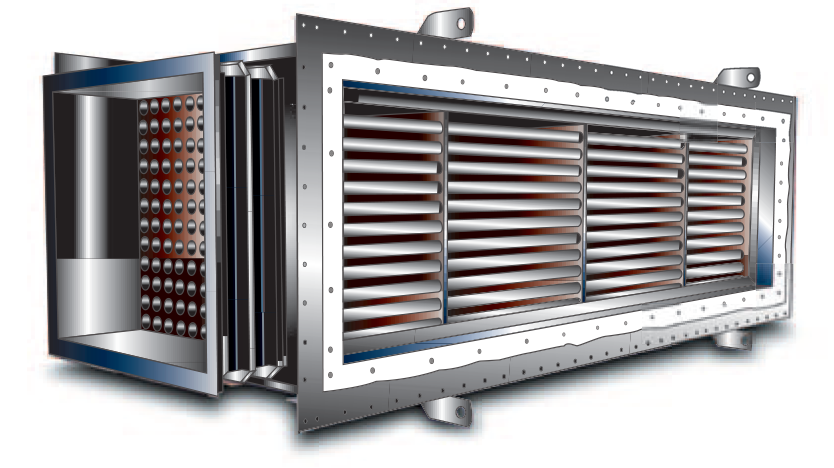

Thermo-T is a welded tubular heat exchanger, custom designed to recover energy from processes up to 1600°F. Energy can be recovered and returned as process make-up air, used to preheat combustion air, or used for plant or office heating. Factory tested for .01% max leakage at standard 20″ W.C. differential pressure rating. Customized for each application with variable tube sizes and spacings, flexible materials of construction, and three (3) flow patterns to simplify ducting. Standard options include 4″ thermal insulation and integral expansion compensation. The Thermo-T can be integrated with a Thermo-Z unit to provide the ultimate in effectiveness, reliability, and value.

Vari-Max® OTH Once-Through Heater

The Vari-Max OTH is a high-efficiency, industrial, indirect-fired gas heater used to heat process air streams without contaminating the air with the products of combustion. The OTH is particularly useful for recirculating ovens, and industrial processes with moderate temperature rises. The counterflow configuration, four-pass design and optimized secondary tubular heat exchanger result in efficiencies up to 85%. The heater uses a Maxon® industrial gas burner for clean, reliable combustion. Standard OTH heat exchangers are constructed of heavy-duty stainless steel for strength, durability, and corrosion resistance. Units are available with FM or IRI certified gas trains and complete heater controls. Des Champs can also provide complete heating. Munters Corp. packages, including filters, dampers, fans, and duct sections or separate housings. The OTH is available in six (6) pre-designed sizes which offer 150°F max temperature rises and exit temperatures up to 600°F.

The Vari-Max IFRG is an ultra-high-efficiency, industrial, indirect-fired gas heater used to heat process air streams without contaminating the air with the products of combustion. The IFRG is particularly useful for spray dryers and industrial processes with high temperature rises. The counterflow heat exchanger with hot side recirculation results in efficiencies of 90%+. The energy savings result in a short payback with savings year after year. The heater uses a Maxon industrial gas burner for clean, reliable combustion. Standard IFRG features include stainless steel heat exchanger, FM or IRI certified gas trains, and complete heater controls. The IFRG is custom designed for each application with 1000°F max temperature rises and exit temperatures up to 1200°F. To further increase efficiency, an optional secondary heat exchanger can be added to capture the energy from the exhaust air and use the energy to preheat the incoming combustion air.

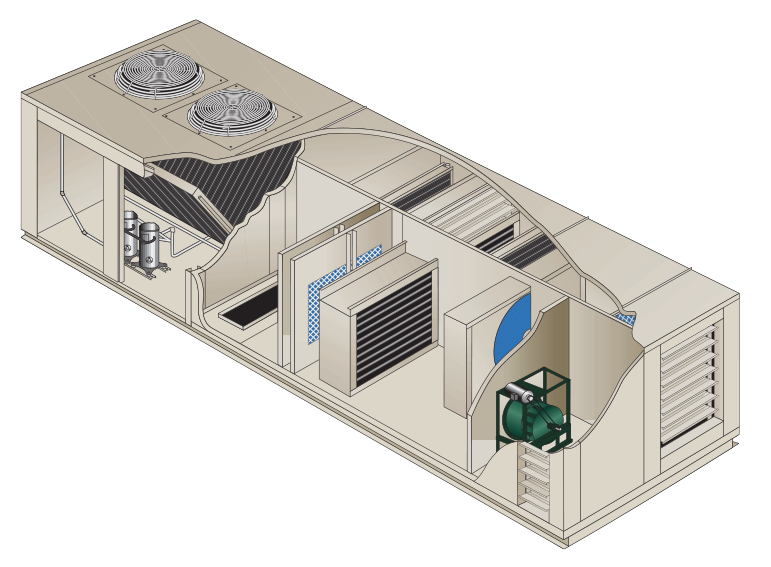

The Wringer Series is a packaged mechanical dehumidification unit designed to supply clean process air at a specific flow and moisture level. It incorporates a heat exchanger to reduce the energy required to dehumidify the air. Wringers are normally employed when the supply air dewpoint requirement is above 40°F. Wringers use approximately 30% less energy than conventional dehumidification systems and provide free reheat. Wringers can incorporate integral refrigeration or utilize chilled water for dehumidification. Options such as auxiliary heating, special filtration, and DDC controls are available.

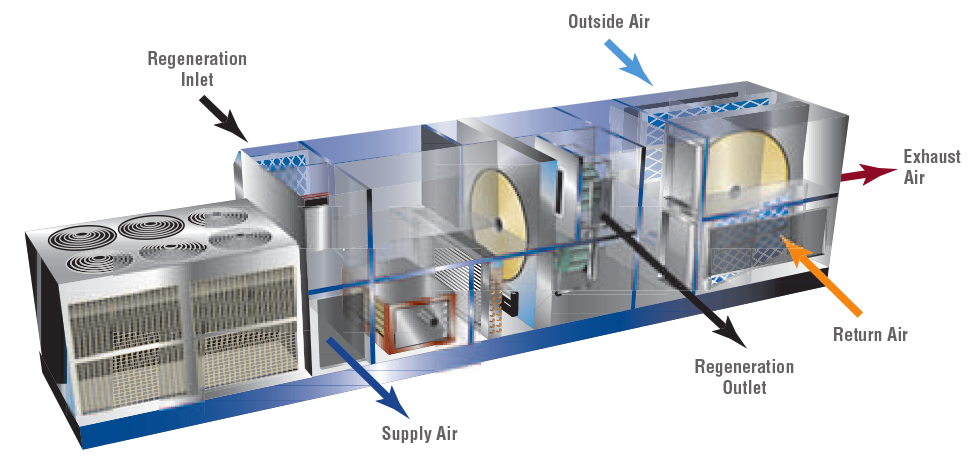

Outside Air The Desi-Wringer Series is a packaged precision desiccant dehumidification unit

Regeneration Inlet designed to supply clean process air at a specific flow and moisture level. Desi-Wringers are normally employed when the supply air dewpoint requirement is Exhaust Air below 40°F or when hot dry air is desired. Discharge air moisture levels as low as –100°F dewpoint can be achieved with this product line. Wheel regeneration options include direct/indirect fired gas, electric, or steam. Energy recovery from waste heat for wheel regeneration or to reduce cooling loads in the process air stream can be integrated into the system as well. Other options such as integral refrigeration, supplemental process air heating, special filtration, and DDC controls are available.

We Strive for Excellence---Our Customers Deserve Nothing Less

For years, Munters has led the air conditioning industry, providing premium-quality energy recovery, dehumidification, and precision air-conditioning equipment. Munters has earned industry recognition and customer loyalty by providing innovative, pre-engineered, fully tested solutions at an economical cost. At Munters, our reputation for excellence is built upon our comprehensive service package: quality products, superior training and an unprecedented extended warranty. When you purchase a product from Munters, you are assured of years of efficient, trouble-free performance.

REQUEST A QUOTE

"*" indicates required fields

Munters

REQUEST A QUOTE

"*" indicates required fields