The IHT Advantage

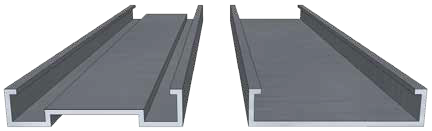

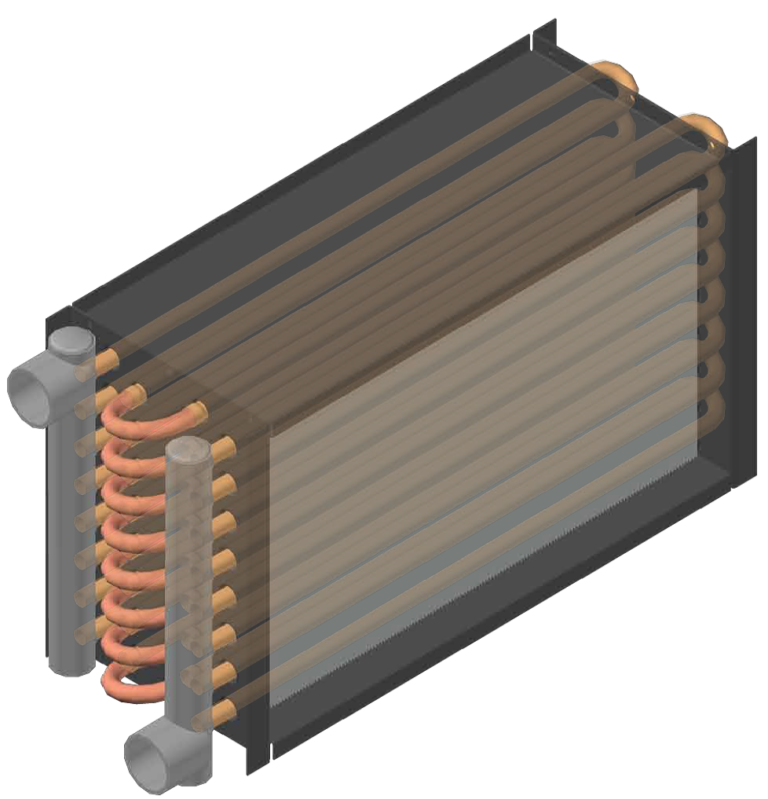

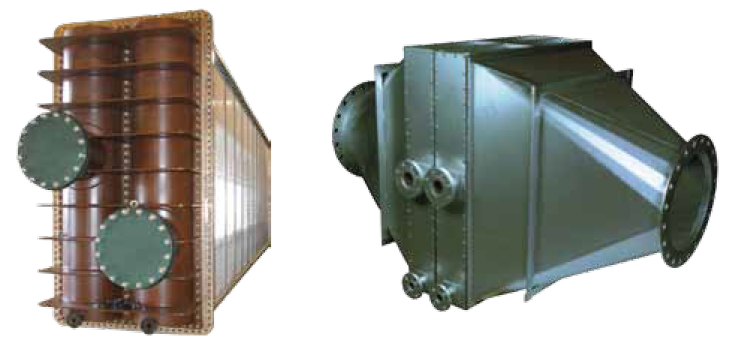

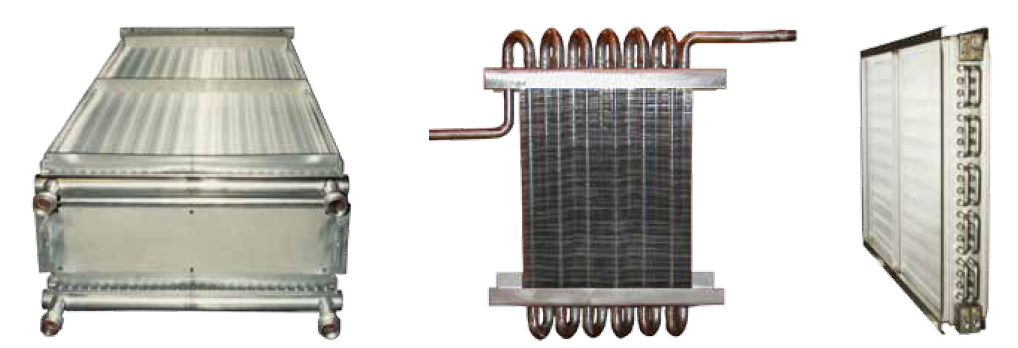

Durable Formed Casing

Coil casings are die formed for high structural strength and rigidity.

Carbon steel, galvanized steel, and stainless steel are standard casing

materials of construction. Other materials are available.

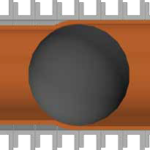

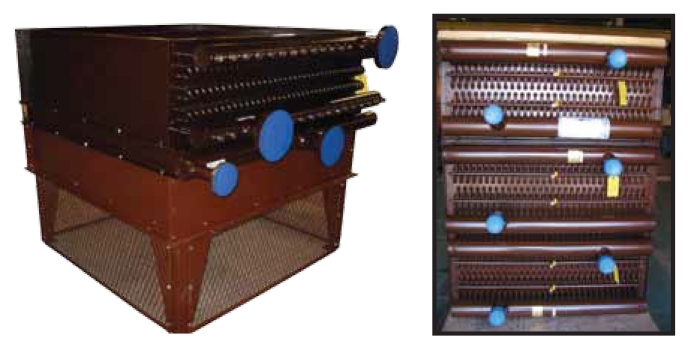

Mechanical Fin-Tube Bond That Lasts:

A permanent fin-tube bond and high transfer efficiency are both ensured by hydrostatically driving an oversized metal ball through the coil tubes. This expands the tube into the fin collars locking a mechanical bond that will last the life of the coil

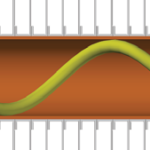

Turbulators:

They are the alternative to multicircuiting of fluid. They cause mixing at lower fluid velocities and enhance the fluid heat transfer coefficient with less than half the pressure drop of half circuited coils.

Permanent Tube Header Joints & High Pressure U-Bends:

Work hardened tubes are rolled or bushed into the headers or tubesheets. All coils with tube and pipe headers have silver brazed or welded joints. U-bends are designed for permanent union and are die formed to provide a generous brazing collar. High temperature brazing alloys and welding fillers are used to withstand high pressures and corrosion potential.

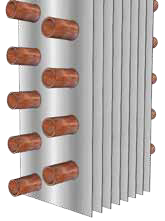

Continuous Plate Fins:

Our fins are strong continuous plates that do not easily bend and

keep the tubes in place. Both flat and wavy type fins are available in

25 different configurations. Many fin materials and thicknesses are available.

Design Codes:

Optional Features:

Outer and Gas Tight Casings

High Pressure Designs

High Temperature Designs

Ducting Transitions

Tube Materials Choices

Fin Material Choices

Fins with Tube Pitch Pattern Choices

Paint and Coating Choices

Custom Designs

Hydrostatic Testing

Custom Configurations

Drain Pans

Material Certifications

Turbulators

Tubesheet Material Choices

Cleanable Tube Designs

ASME Code Stamp

Header Material Choices

Air Tight Casings and Transitions:

IHT also offers leak-proof, air tight casings, including designs with removable coils. Casings are usually made of Galvanized or Stainless sheet metal and keeps gases from either entering or leaving the duct. Pressure retaining circular duct transitions can either be welded or bolted to the air tight casing. Circular flanged connection

points act as easy junctions to existing duct lines.

Coil Applications

CUSTOM DESIGNS FOR ANY APPLICATION

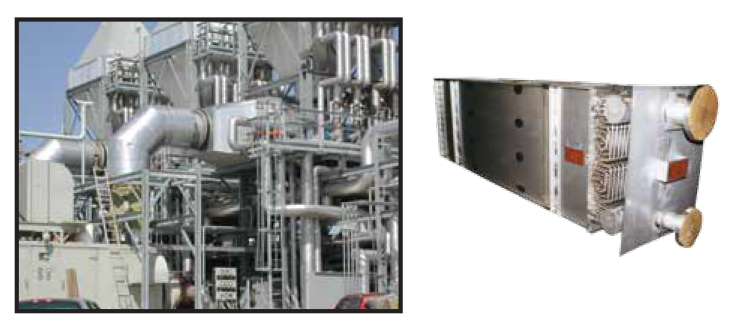

Turbine Inlet Cooling

Fan Cooled Units

Intercoolers & Aftercoolers

Waste Heat Recovery

Motor / Generator Coolers

Marine Environments

Steam Coils

Transformer Oil Coolers

Military Specification

AND MORE...

Ovens, Dryers, and Furnaces

Food Processing

Pulp & Paper Manufacturing

Standard OEM Designs

Typical materials of construction include:

FINS:

TUBING:

Aluminum

Copper

Stainless Steel

Carbon Steel

Copper

Stainless Steel

Carbon Steel

90/10 Cupro-Nickel

Red Brass

Aluminum

Inconel

Admiralty

Southgate Proccess Equiptment, Inc

87 Hickory Springs Industrial Dr. Canton, GA 30115

Phone: (770) 345-0010 Email: Sales@southgateprocess.com

Other materials and applications are available

INDUSTRIAL HEAT TRANSFER, INC.

REQUEST A QUOTE

"*" indicates required fields