DELTA T THERMAL SOLUTIONS

Southgate Process Equipment is an authorized distributor for Delta T Thermal Solutions, a Sharp Iron Group Company.

Southgate maintains a large inventory of complete units and spare parts in stock for fast deliveries. If you need a particular part or item please click here to request a quote or call us @ (770) 345-0010.

Delta T Thermal Solutions is the global based manufacturer of PLATECOIL®, MAXCHANGER®, AND ECONOCOIL® heat transfer product lines. With Delta T Thermal Solutions, customers find efficiency, versatility, quality construction, and extensive knowledge of heat exchange technology and products. Delta T Thermal Solutions is your global solutions provider for all your heat transfer needs.

Delta T Thermal Solutions is the global based manufacturer of PLATECOIL®, MAXCHANGER®, AND ECONOCOIL® heat transfer product lines. With Delta T Thermal Solutions, customers find efficiency, versatility, quality construction, and extensive knowledge of heat exchange technology and products. Delta T Thermal Solutions is your global solutions provider for all your heat transfer needs.

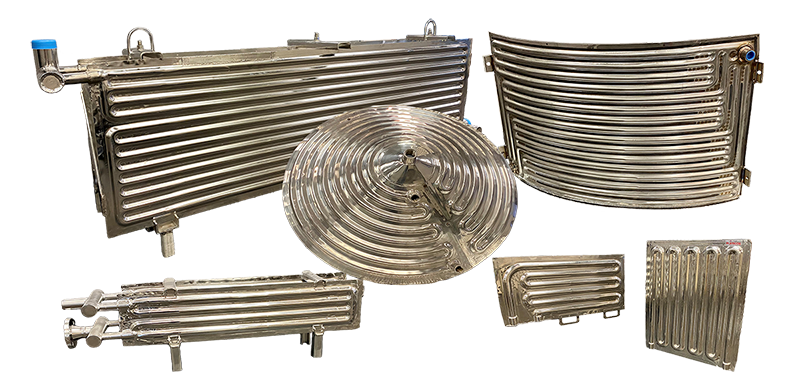

PLATECOIL®

Delta T Thermal Solutions PLATECOIL® is a very efficient and versatile light-duty plate-type heat exchanger. Its unique construction enables high heat transfer efficiency for heating and cooling, which can be applied to a wide range of applications. Units are commonly used in the plating, metal finishing, chemical processing, pulp & paper, waste treatment, textiles, pharmaceutical, and food & beverage industries.

PLATECOIL® is fabricated from two sheets of metal using a fully computerized welding machine that uses electric roll spot resistance welding. The plate is then hydraulically inflated, forming a variety of flow patterns. Each ECONOCOIL® plate is designed and constructed to match the needs of each application and requirement.

PLATECOIL® units are usually constructed out of carbon steel, 304 and 316 stainless steel materials. Other materials we do offer are monel, inconel, hasealloy, alloy 20cb-3, 254-SMO, AL6XN, and titanium.

Multi-zone PLATECOIL® units are ideally used when steam is heating the medium. With its zoned header design, Multi-Zone PLATECOIL® provides far more heat transfer efficiency than pipecoil or units with straight headers in applications requiring the use of steam. The Multi-Zone headers and flow arrangement provide controlled distribution of the steam as it flows through the PLATECOIL®. The rate of condensate removal from the passages or passes is significantly increased as compared to units with straight headers. Efficiency reducing condensate blocking is minimized. As a result, Multi-Zone PLATECOIL® provides faster heat-up and better heat transfer rates.

Serpentine PLATECOIL®: with a Serpentine flow configuration provides outstanding performance with liquid heating or cooling media, because its configuration allows high internal flow velocities to be achieved. As a result, high heat transfer rates can be obtained. Serpentine PLATECOIL® is frequently specified for use with cold water, high temperature hot water, hot oil and refrigerants. When used with refrigerants, the Serpentine flow design offers the additional advantage of eliminating the possibility of “short-circuiting”.

Both Multi-zone PLATECOIL® and Serpentine PLATECOIL® styles available in over 300 standard sizes. Widths range from 12″ to 43″. Lengths range from 23″ to 143″. Custom units for your specific application are available in many sizes and material configurations. This can be paired with any of our accessories such as handles, hangers, lugs, or special connections.

PLATECOIL® Applications

- Immersion Heaters and Coolers

- Jacketed Tanks and Vessels

- Clamp-On Upgrades

- Heat Recovery Banks

- Fluidized Bed Banks

- Cryogenic Shrouds

- Cascade Coolers

- Freeze Dry Condenser Banks

- Shipboard Heaters and Coolers

- Storage Tank Heaters

- Shelves

- Glycol Dehydrators

- Paint Solvent Coolers

- Water-Cooled Shields for Electric Furnaces

- Water Chillers for Soft Drink Carbonators

- Valve Warmers

- Banks for Waste Heat Recovery

- Refrigeration Coolers

- Refrigerated Liners for Medical Testing Machines

- Suction Heaters

- Screw Conveyer Troughs

- Bayonet Heaters

- Drum Warmers

- Pipe Coolers

- Gas Cylinder Heaters

- Sanitary/Hygienic processing

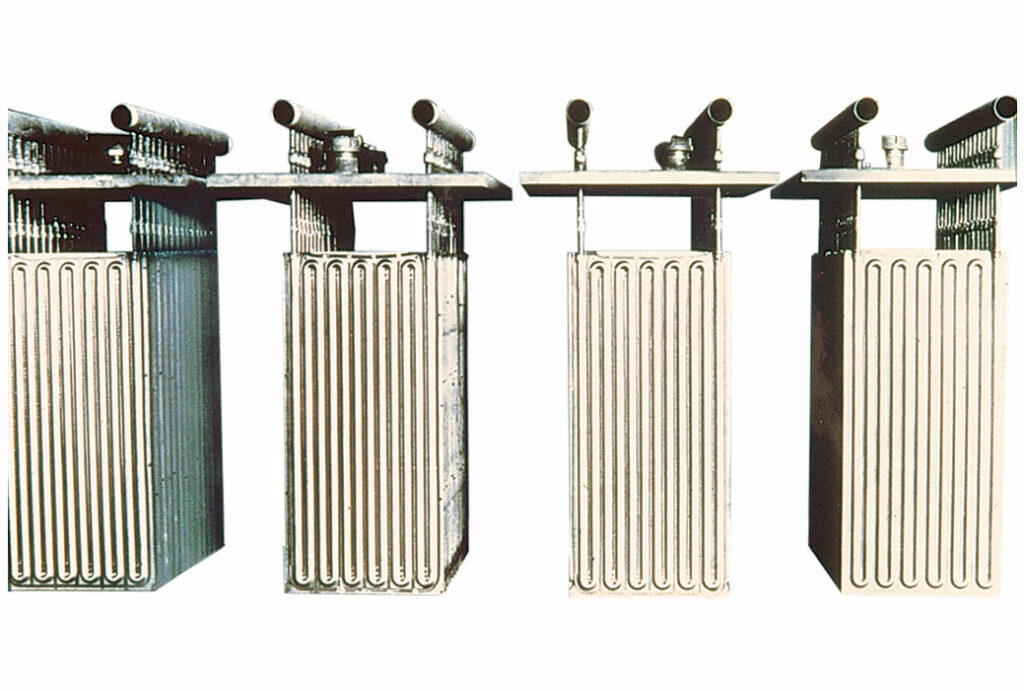

MAXCHANGER ®

MAXCHANGER® single- and multiple-pass designs fit virtually any application requirement. The unique geometry of the patented MAXCHANGER®’s variable interspaces produce extremely high “U” values. Channels formed between the specially dimpled, welded plates direct the two heat transfer media counter currently through alternate paths for maximum efficiency, immediate thermal response and a close temperature approach capability of less than 1°C (2°F).

The corner angle fittings or corner half-pipe fittings, enable inlets and outlets—NPT or flanged—to be located in any number of configurations for maximum flexibility in tight spaces.

The 1-mm (0.039-in.) thick dimpled heat exchanger plates are sandwiched between top and bottom plates specified to withstand the design pressure. Special spacers separate the plates, isolating the channels and establishing countercurrent flow. Four corner angles (or half-pipes) are welded to side plates, top and bottom plates and to the heat exchange plate points, forming inlet and outlet headers.

MAXCHANGER® Applications

Power Generation

• Low pressure feedwater heaters

• Condensate exchangers and condensate trim coolers

• Blowdown heat recovery exchangers

• Condensers and vapor condensers

• Condensate subcoolers

• Evaporators

• Molten salt to thermal fluid interchangers

• Seal water coolers

• Closed cooling loop exchangers

• Component cooling water (CCW) exchangers

• Lube oil coolers

• Gland steam condensers

• Recuperators

• Economizers

• HRSG (Heat Recovery Steam Generator) cross exchangers

Refrigeration

• Flooded evaporators with surge drum, condensers, chillers

• Liquid chillers for flooded evaporation

• Flooded evaporators with pumped refrigerant feed

• Liquid-cooled condensers

• Cascade CO2 condensers for flooded ammonia and other refrigerants

• Thermosyphon oil coolers

• Oil coolers and condensate subcoolers for flooded evaporation

Chemical Processing & Pharmaceuticals

• Optimization of condensation, heating/cooling, mist elimination, heat recovery and reboiling systems

• Evaporation, distillation and condensation of substituted olefins and aromatics, including halogenated compounds

• Thermal processing involving mineral acids and caustics

• Viscous processing with monomers and resins

• Soaps and detergents, paints and coatings

• Mineral oil heating and cooling

• Gas cooling and drying: chlorine, hydrogen, nitrogen, carbon dioxide

• Vapor and solvent recovery

Oil & Gas Production & Refining

• Optimization of heat recovery, cooling, condensation, dehydration and reboiling systems

• Distillation column exchangers: fractionators, hydrocrackers, recrackers and hydrogen sulfide strippers

• Waste heat recovery and feed water heating

• LPG reliquefaction

Emissions Control Systems

• Ammonia liquor scrubber coolers

• Flue gas heat recovery banks

• Flue gas reheating banks

• Mist elimination banks

Food Processing

• Vegetable oil heating

• Waste heat recovery

HVAC And District Heating

• Steam and hot water heaters

• Heat recovery exchangers

• High temperature interchangers

• Water/glycol-cooled oil coolers

• Discharge gas desuperheaters for heat recovery

ECONOCOIL ®

Delta T Thermal Solutions ECONOCOIL® is a very efficient and versatile light-duty plate-type heat exchanger. Its unique construction enables high heat transfer efficiency for heating and cooling, which can be applied to a wide range of applications. Units are commonly used in the plating, metal finishing, chemical processing, pulp & paper, waste treatment, textiles, pharmaceutical, and food & beverage industries.

ECONOCOIL® is fabricated from two sheets of metal using a fully computerized welding machine that uses electric roll spot resistance welding. The plate is then hydraulically inflated, forming a variety of flow patterns. Each ECONOCOIL® plate is designed and constructed to match the needs of each application and requirement.

ECONOCOIL® Applications

- AImmersion Heaters and Coolers

- Jacketed Tanks and Vessels

- Clamp-On Upgrades

- Heat Recovery Banks

- Fluidized Bed Banks

- Cryogenic Shrouds

- Cascade Coolers

- Freeze Dry Condenser Banks

- Shipboard Heaters and Coolers

- Storage Tank Heaters Shelves

- Glycol Dehydrators

- Paint Solvent Coolers

- Water-Cooled Shields for Electric Furnaces

- Water Chillers for Soft Drink Carbonators

- Valve Warmers

- Banks for Waste Heat Recovery

- Refrigeration coolers

- Refrigerated Liners for Medical Testing Machines

- Suction Heaters

- Screw Conveyer Troughs

- Bayonet Heaters

- Drum Warmers

- Pipe Coolers

- Gas cylinder heaters

- Sanitary/hygienic processing

One of the best benefits of ECONOCOIL® is that it can be produced in an extensive range of custom-made variants when needed for special applications. For example, Delta T Thermal Solutions can alter the connection location and length, creating an irregular-shaped curved ECONOCOIL® to fit a tank cone end. Another application example is Delta T staff can weld several plates together to form banks which can be used for large heat exchanger duties and provide accessories to assist with installation and maintenance.

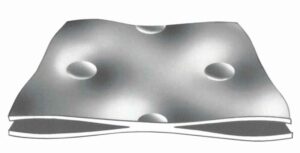

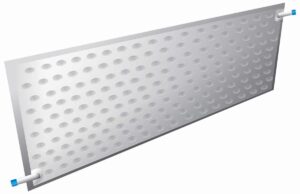

There are two main types of ECONOCOIL®, which determine the unit’s structure. These are double embossed and single embossed.

Double Embossed ECONOCOIL®

Single Embossed ECONOCOIL®

Delta T Thermal solutions can manufacture ECONOCOIL® in a massive variety of shapes and sizes to suit all purposes. There are five basic styles to fit specific applications, with all styles available in double and single embossed forms in numerous configurations. All units are supplied with BSPT Male Threaded Connections as standard. However, we can provide a variety of connection options. For Styles EC70, EC80 & EC90, the connection size depends on the plate dimensions.

Delta T Style EC50

Style EC50 ECONOCOIL® is largely used for heating and cooling while immersed in tanks. Therefore, its design is most suitable for liquid-to-liquid duties such as heating oil with hot water. Easy lift handles can be attached with hangers available to make installation alongside a tank wall as simple as possible.

Delta T Style EC60

Style EC60 ECONOCOIL® is widely used for high-velocity media to generate a high-pressure drop which gives accelerated heat transfer. It is commonly used with water, hot oil, and direct expansion refrigerants. Handles can be attached along the width to allow tank immersion.

Delta T Style EC80

Style EC80 ECONOCOIL®’s primary use is for external Clamp-On ECONOCOIL® for maintaining applications. It’s predominantly effective with high flow rate fluids as it creates minimum pressure drop. Clamp-On EC80 Econocoil units are normally supplied with attachment lugs and heat transfer mastic.

ECONOCOIL® Accessories & Options

With each ECONOCOIL®, Delta T Thermal Solutions can offer a range of options and accessories to assist Installation and improve performance. For ECONOCOIL® to be used in tanks, we offer handles and hangers so they will be correctly positioned and can easily be inserted and removed. For clamp on applications, we offer Konduct No.1 Heat Transfer Cement to assist with heat transfer. Additionally, we supply lugs with tie bolts to securely fasten the ECONOCOIL® to surface sides.

REQUEST A QUOTE

"*" indicates required fields