ADVANTAGE

Southgate Process Equipment is a top authorized distributor for Advantage Engineering. If you are requiring a specific part or item, please click here to request a quote or call us @ (770) 345-0010.

Advantage Engineering offers more than 40 years of process cooling experience. Our knowledgeable application, product and service specialists are always available to discuss your needs and help you find the best solution for your specific requirements.

Advantage Engineering offers more than 40 years of process cooling experience. Our knowledgeable application, product and service specialists are always available to discuss your needs and help you find the best solution for your specific requirements.

We have experience in a wide range of industries that require process cooling including plastics processing, die casting, machine tool, vessel cooling and many others. You can trust our knowledgeable people will understand your specific needs and provide the optimal solution.

We build our own system controls from a combination of tailor made embedded microprocessor products and PLC options, allowing us to configure the perfect purpose built control system to meet your needs. System drawings, including custom plant layout, are provided with the purchase of all Advantage water systems.

Advantage is a leading manufacturer of Chillers and Accessories.

The Advantage product catalog consists of a wide array of heat transfer products including:

Temperature Controllers:

DETAILS on ADVANTAGE Sentra and Regal Series Temperature Controllers:

Advantage temperature controllers circulate fluid through a process application for heating or heating and cooling. Temperature controllers supply fluid temperatures from 30° to 500°F. Our Sentra Series circulates water through the process, and our Regal Series uses oil as the fluid, allowing for much higher process temperatures.

- Contact Us for Best Prices! (770) 345-0010

- Cooling water supply for the Sentra is required from an external source.

- 30° to 300°F Process Temperatures

- 6 to 34 kW Heaters

- 1/2 to 7.5 HP Centrifugal Pumps (20 – 100 GPM)

- 1/2 inch and 3/4 inch AVT™ Modulating Cooling Valves (LE & HE models)

- 3/8 inch – 1 inch Solenoid Cooling Valves (VE & 300°F models)

- 100° to 500°F Process Temperatures

- 12 to 48 kW Heaters

- 1 to 7.5 HP Centrifugal Pumps (20 – 100 GPM flow rates)

- 3.6 square foot Heat Exchanger (included on HC models)

- Choice of Microprocessor Control Instruments

Central Water Chillers:

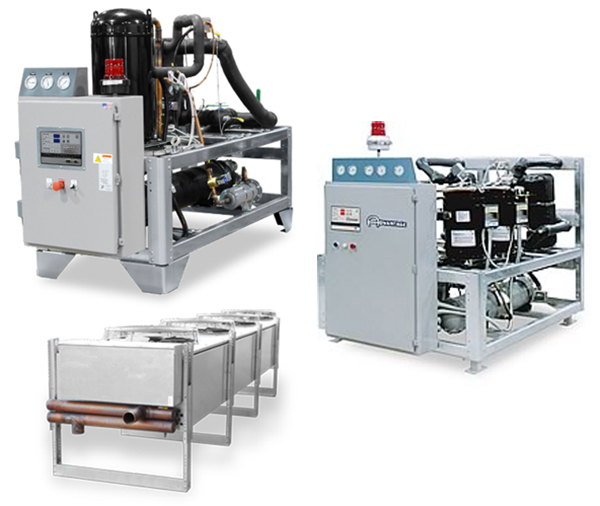

DETAILS on ADVANTAGE WPT, APT-RC, OACS, and Titan Series Central Water Chillers :

Central Water Chillers service multiple use points throughout the plant. Central chillers are stationary, and require a circulating system to distribute water to the process. Central chillers are offered in capacities from 20 to 500 tons.

ADVANTAGE central chillers are offered as MODULES and PACKAGES. A module is a stand-alone chiller unit that requires a pump tank station to distribute the chilled water. A package is a self-contained unit with the chiller and pump tank station on a single platform.

- Contact Us to Request a Quote on the best Central Water Chiller to fit your needs! (770) 345-0010

- 5 – 180 tons of Cooling Capacity

- Provide a coolant temperature range between 20˚F and 80˚F when using R410A refrigerant

- Equipped with Hermetic Scroll Compressors or Tandem Scroll Compressors

- 5 – 180 ton Models

- 20˚ – 80˚F Fluid Temperature Range

- Available in Single, Dual, and Triple Refrigerant Models

- Uses a Non-Ozone Depleting Refrigerant

Advantage OACS systems are designed to be installed outside using no valuable indoor floor space and are a complete package including water reservoir and pumping system. The system is fully factory tested before shipment and requires minimal installation.

OACS systems are available with 1 or 2 independent refrigeration zones for energy efficient capacity staging and to provide partial or full redundancy.

- Complete Central Chiller System with Integrated Reservoir and Pump all mounted on a single frame

- Outdoor Installed Air-Cooled Design

- 5 – 210 ton Models

- 20˚ – 80˚F fluid temperature range for models

using R410A refrigerant - 20˚ – 65˚F fluid temperature range for models

using R407C refrigerant

Advantage Titan Central Chillers configured with reservoir and pumps housed in a single frame – making it a complete self-contained package which reduces installation costs compared to other systems.

The Titan systems can be air-cooled or water-cooled. Air-cooled models require an outdoor remote condenser. Water-cooled models require an external water supply source such as cooling tower, city or well water to reject the heat removed from the refrigeration circuit.

Both air-cooled and water-cooled Titan Chillers can be configured for future expansion to meet your growing cooling needs with the addition of APT or WPT chiller modules.

- 20 – 180 tons of Cooling Capacity

- 20˚ – 80˚F fluid temperature range when using R410A refrigerant

- Complete self-contained package

- Air-Cooled or Water-Cooled models available

Portable Water Chillers:

DETAILS on ADVANTAGE Portable Water Chillers :

Advantage Portable Chillers supply temperatures between 20° to 70°F, are self contained units, and use a refrigerant system to chill water. The chilled water is stored in a reservoir and supplied to the process using a circulating pump.

Custom designed microprocessor instrumentation control the unit’s operation. Portable chillers can service single or multiple process cooling points, and are designed to be moved between process applications as needed.

- Contact Us to Request a Quote on a Portable Chiller Package to suit your needs! (770) 345-0010

Advantage’s purpose built Air-Cooled Portable Chillers for EDM Machine Cooling Applications provide these features:

- Indoor Units

- Air-Cooled Condenser

- 20˚ – 80˚F Fluid Temperature Range

- Non-Ozone Depleting Refrigerant

Advantage’s Maximum Series Portable Chillers are refrigeration units coupled with an integral fluid circulation system. They range in cooling capacity from 1/4 to 40 tons. These units are used to cool fluids to support industrial process cooling applications requiring a fluid temperature range from 20˚ to 80˚F.

- Indoor Units

- Easy Installation, requiring only a source of electrical power, coolant fluid, and a process load to be temperature controlled

- Available in Air-Cooled or Water-Cooled models

- Can be configured with a remote, air-cooled condenser to decrease heat within your facility

- 1/4 – 40 ton Cooling Capacity

- 20˚ – 80˚F Fluid Temperature Range

- Comes Fully Charged with Non-Ozone Depleting Refrigerant

Evaporative Cooling Towers:

DETAILS on ADVANTAGE Power Tower Series Evaporative Cooling Towers:

Through extensive development and testing, the Power Tower cooling tower cells are space efficient, highly versatile and have a lower first cost and operating cost when compared to other cooling methods.

Advantage’s Power Tower is simple to operate with easy to understand controls and utilizes energy-efficient evaporative cooling to provide cooled water for a variety of industrial applications and equipment. Power Towers receive warm water returning from the process and evenly distribute it over the wet deck using a water distribution header and spray nozzles. A direct drive fan draws air from the inlet louvers, through the wet deck, and out the top of the tower.

The falling water and counter airflow causes a portion of the warm process water to evaporate. The small amount of water evaporating cools the remaining water. Under design conditions about 1% of the water flow rate evaporates to achieve the cooling affect desired.

- Built for the Industrial environment

- Long lasting: All wetted surfaces are made of fiberglass, stainless steel, PVC or other non-rusting material

- Reduced Maintenance: Closed loop system with only one moving part requiring periodic lubrication

- Easy to Install with clearly labeled process connection and a steel base for easy rigging and mounting

- Contact Us for more information on Advantage Power Tower Evaporative Cooling Towers! (770) 345-0010

Advantage’s Power Tower Series Evaporative Cooling Towers are made of durable UV protected fiberglass with a counter air flow design.

- Space and Energy Efficient

- Capacities from 45 to 540 tons

- Maintains full capacity and temperature control stability over a wide range of wind, air temperature, and humidity extremes

- Nominal rating condition is cooling 3 gallons per minute per ton of capacity from 95°F to 85°F at 78°F wet bulb

- Materials are design for constant water contact under hot and cold air temperature extremes

- Fiberglass shells up to 1/2″ thick in structural areas for mechanical integrity and long service life

Pump Tank Stations:

DETAILS on ADVANTAGE TTK Tough Tank & PTS-CPTS Pump Tank Stations:

Advantage Pump Tank Stations are an integral part of evaporative cooling tower, fluid cooler and chilled water cooling systems. Pump Tank Stations provide a stable reservoir of cooling fluid that minimizes the affects of cooling load changes.

Pump Tank Stations are generally installed indoors and consist of a vented reservoir along with fluid pumps and controls that are selected to meet the specific needs of your system. The vented reservoir provides natural air separation for any air that may be trapped in the cooling fluid which reduces heat transfer effectiveness as well as providing a convenient location to monitor water quality and introduce chemical treatment.

- Available in 1-Pump and 2-Pump System Configurations

- A 3/8″ dense foam insulation is applied to the outside of the reservoir on chilled water systems to prevent sweating and heat gain (Tough Tank & CPTS only)

- Can be equipped with controls as basic as manual push button motor starters and thermostats to more advanced controls such as the CheckMate System Control & Monitoring System

- Contact Us today for more information on Advantage Pump Tank Stations! (770) 345-0010

Advantage Tough Tank is a one-piece, cylindrical, seamless, rotationally molded linear low density polyethylene tank that will not rust or corrode.

The Tough Tank includes a drain valve, mechanical water make-up system and overflow port creating a fully engineered package ready to run.

- 400, 800, 1,500 & 3,000 gallon capacities

- Hinged tank lid for easy access

- On 2-pump systems, an internal baffle provides hot/cold water service

- A sight tube provides easy level verification

- 10 year tank failure warranty

Advantage PTS-CPTS Reservoir Pump Tank Stations are constructed from epoxy coated mild steel or stainless steel welded sheet.

The PTS-CPTS includes a drain valve, mechanical water make-up system and overflow port creating a fully engineered package ready to run.

- 275 – 3,000 gallon capacities

- Internal baffle provides hot/cold water service (2-pump systems)

- 1 year warranty

For more information on Advantage Engineering and their products

please email us at sales@southgatepe.com or call us at (770) 345-0010.

We look forward to helping you with all your Advantage product needs.

REQUEST A QUOTE

"*" indicates required fields